The ‘Stovebolt’ Chevy 235 Engine

Believe it or not, the original Corvette carried one flavor or another of the the infamous Chevy 235 cubic inch, inline 6 cylinder engine between 1953 and 1956 and Chevrolet crammed it into every truck between '54 and '62. While it didn't earn any marks in terms of performance, its selling point was durability.

The engine is nicknamed the stovebolt because the valve cover, timing cover, and lifter cover all used bolts that looked like the slotted-head, course thread fasteners you'd find in an old wood burning stove.

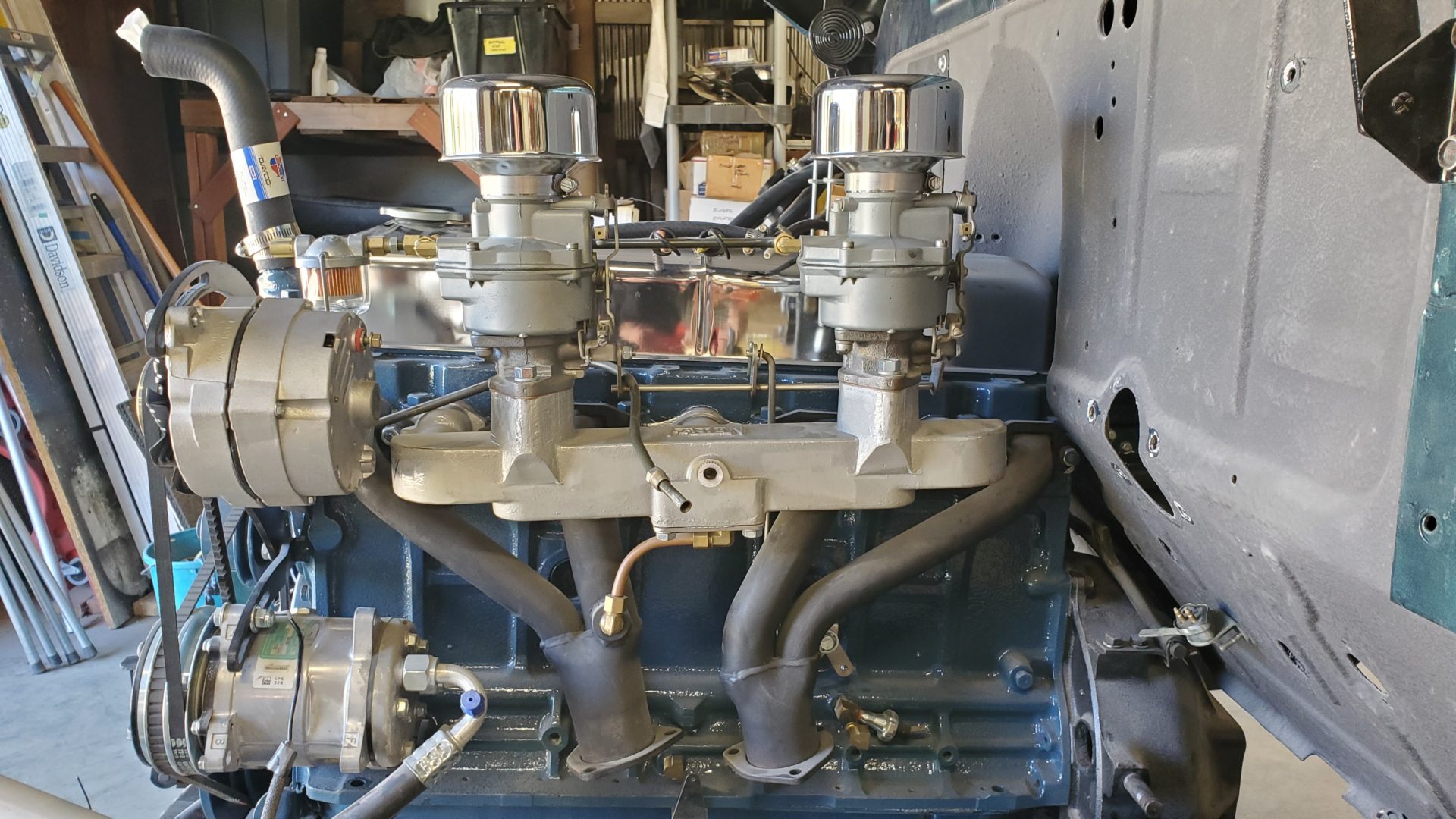

This truck has a 235 powerplant painted a shiny blue. Someone added a Fenton dual carb intake with new carburetors, a dual outlet exhaust header, and chrome valve cover. When it arrived, and based on appearance alone, we assumed the engine had been completely rebuilt as part of the restoration.

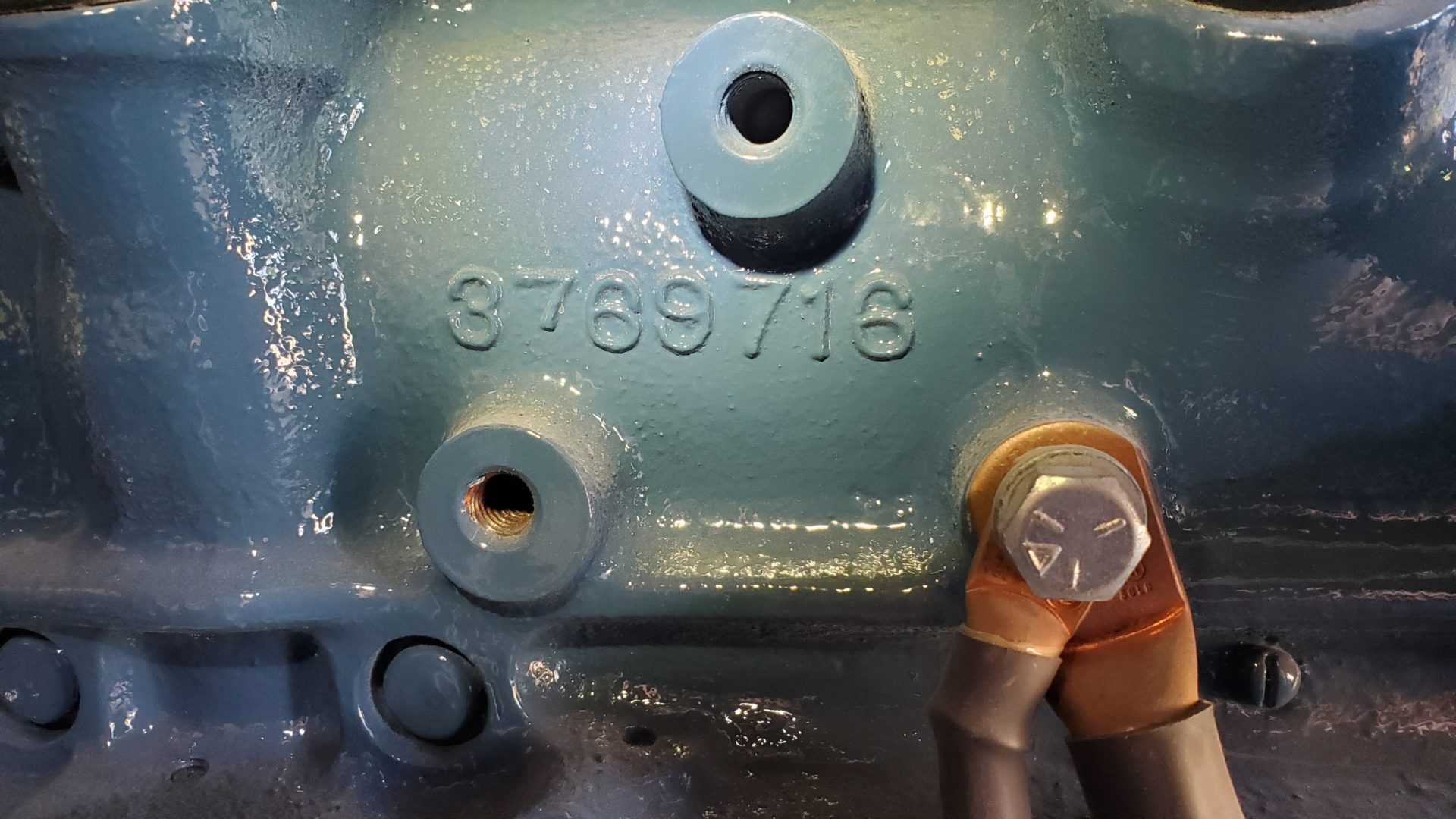

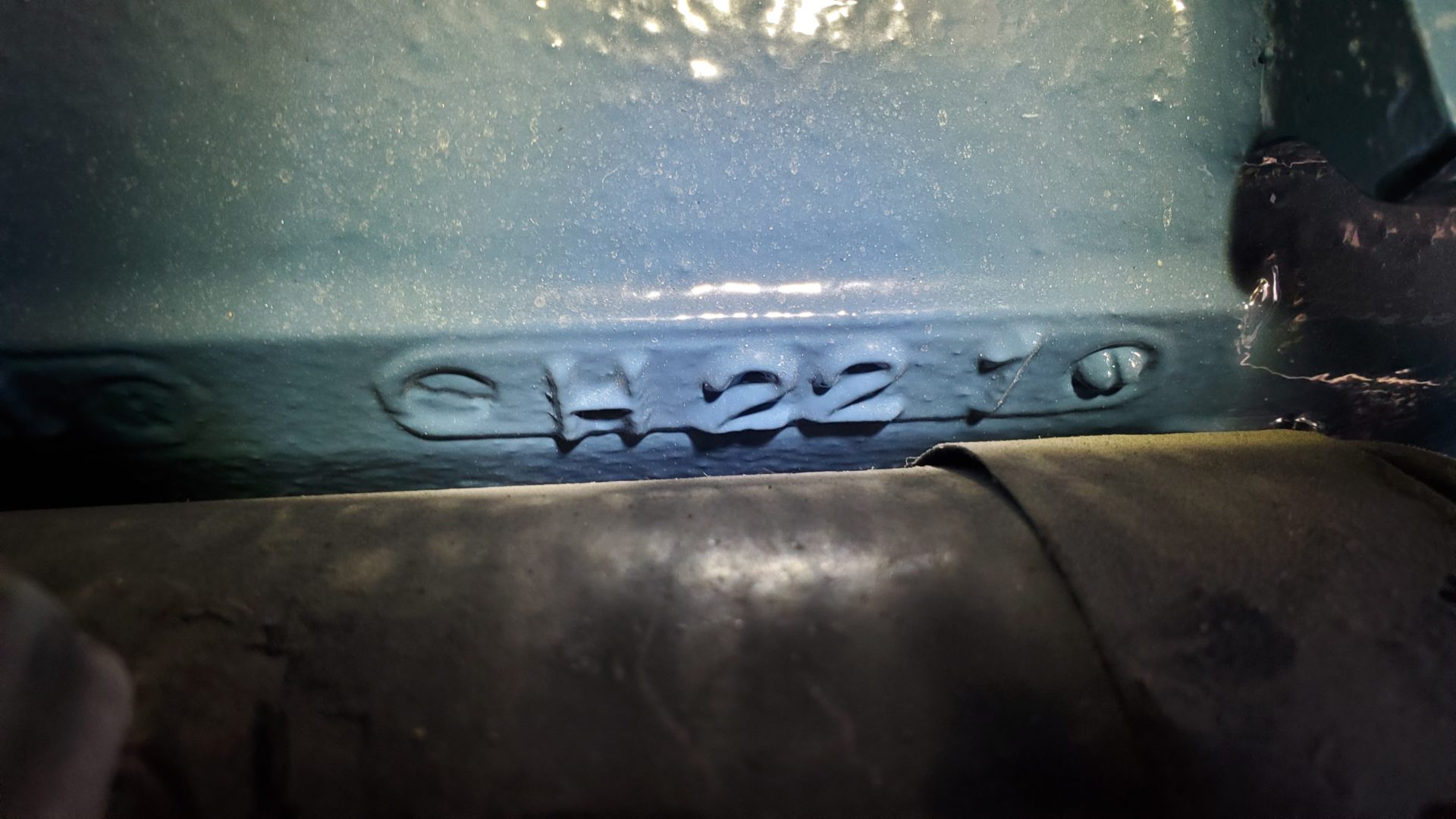

The various external casting numbers on the engine revealed some other facts. There's an engine block casting number, a block casting date, and a serial number for the completed engine stamped near the distributor that provides a clue as to what the engine was intended for. And finally, there's a number cast into the head.

A little online research shows our engine block casting number (3769716) applies to engines manufactured between 1958 and 1962.

The casting date (H221) decodes to August 22, 1961 (it came down conveyor 4).

The serial number (F0824B) decodes to the Flint, Michigan plant - August 24 - and a regular 235 with a Powerglide automatic transmission behind it. (So, a car).

The head casting number (3701887) applies to 1953 235's for trucks which was the last year for 'low-pressure oil system' engines.

Yes, more trivia than you ever cared to read about! The bottom line is, the engine is a collection of parts all newer than the rest of the truck. It looked fresh and hadn't been started since painted. The real question for us was: Is this a complete rebuild that needs a proper break-in when the time comes to start it, or not? Well, you know what they say about about the word 'assume'.

So, we pulled out an endoscope camera to have a peek inside. It wouldn't tell us everything, but could provide some valuable clues one way or another. Have a look for yourself...

The question remains whether a new camshaft and lifters were installed as part of the reseal and paint job. No way to tell for sure without a a partial disassembly - which we really don't want to do if not absolutely necessary. In all likelihood a new cam was not installed (there's that word 'assume' again) and no special startup and break-in period will be called for. We'll ask the owner if he has any information.

We'll also have a look inside the intake and other cylinders for the unlikely but possible chance there's a rodent nest or something that might account for the unidentified, funky looking junk on the piston.

This project continues to dish the mysteries. Stay tuned for more!