If Old Trucks Could Talk…

If this old '50 Chevy truck could talk it would just laugh - mock me, really. I'll explain later.

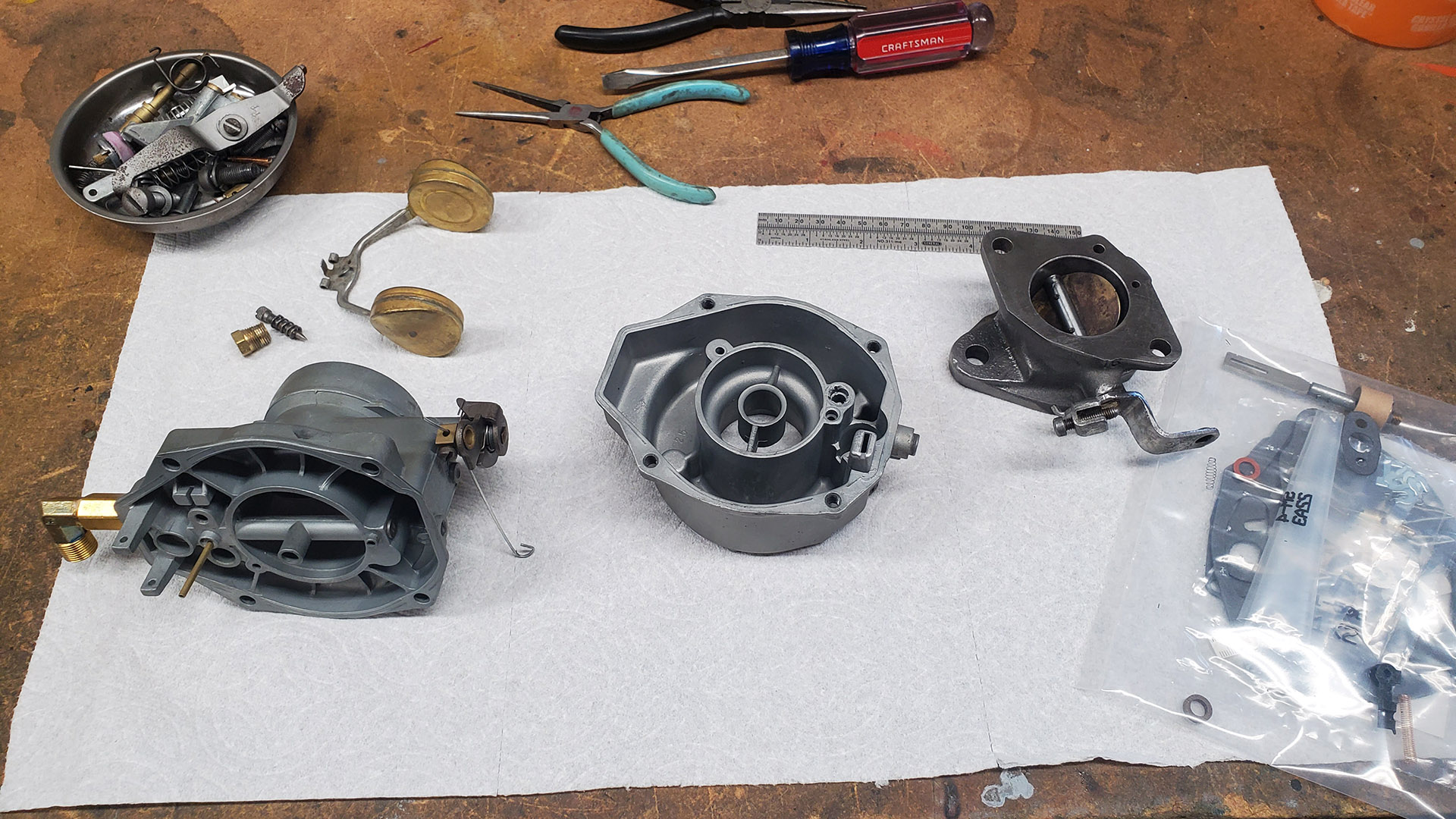

Two Rochester 'B' carburetor kits showed up from Mikes Carburetor Parts located right here in Washington. He sells parts for all the old stuff.

Pretty routine stuff. What was key in this case were the new bowl gaskets and accelerator pumps. But the carbs got all the new bits they would accept.

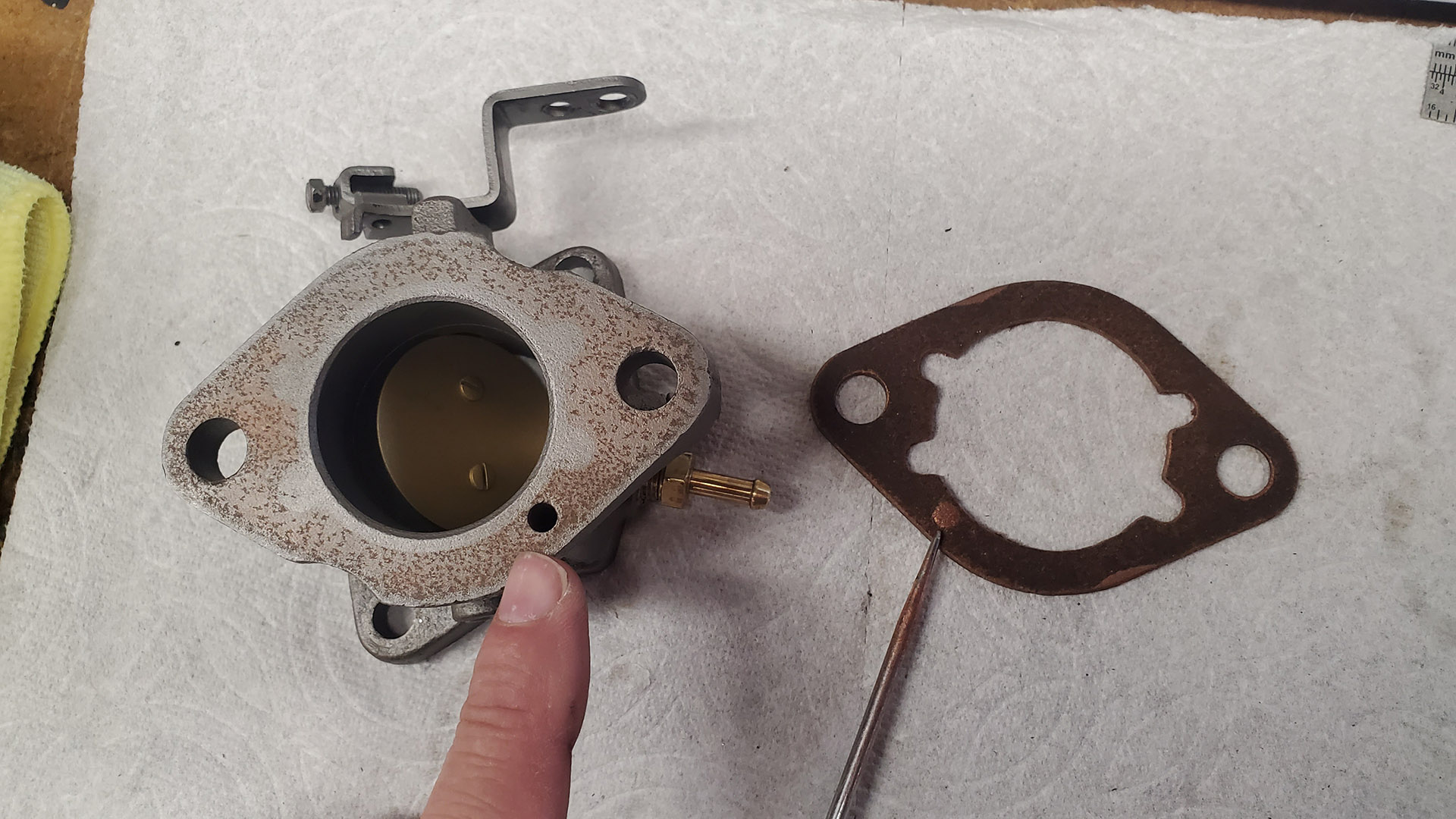

One potential issue noticed and overlooked by previous tinkerers is an important vacuum passage on these carburetors. It's located on the base and is supposed to send a vacuum signal to the 'power' circuit inside the carburetor to add extra fuel under acceleration.

If this port is blocked (no vacuum) then extra fuel will added all the time for an overly rich mixture when you don't need it. Not good.

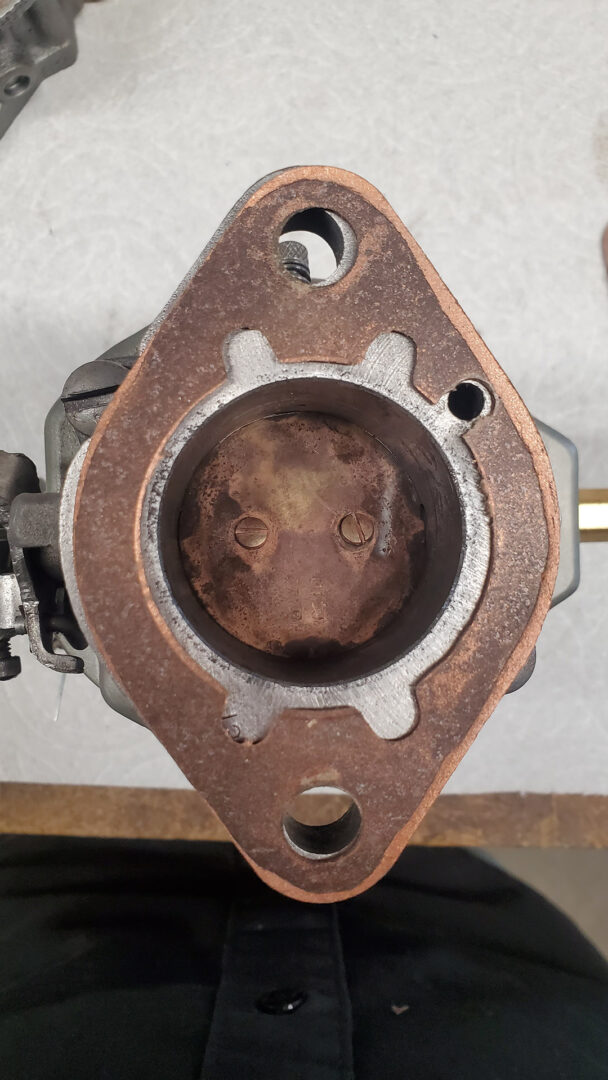

Originally, these old engines had a insulator/spacer between the carb and intake. The spacer had a divot built into it so that engine intake vacuum could reach the port. If you look closely at the photo below it even has the word 'TOP' cast into it.

Without two of these spacers, the workaround is to add a cutout to the base gaskets. Mike's actually sells these carb base gaskets with the extra vacuum ports.

I took a hole punch and created them.

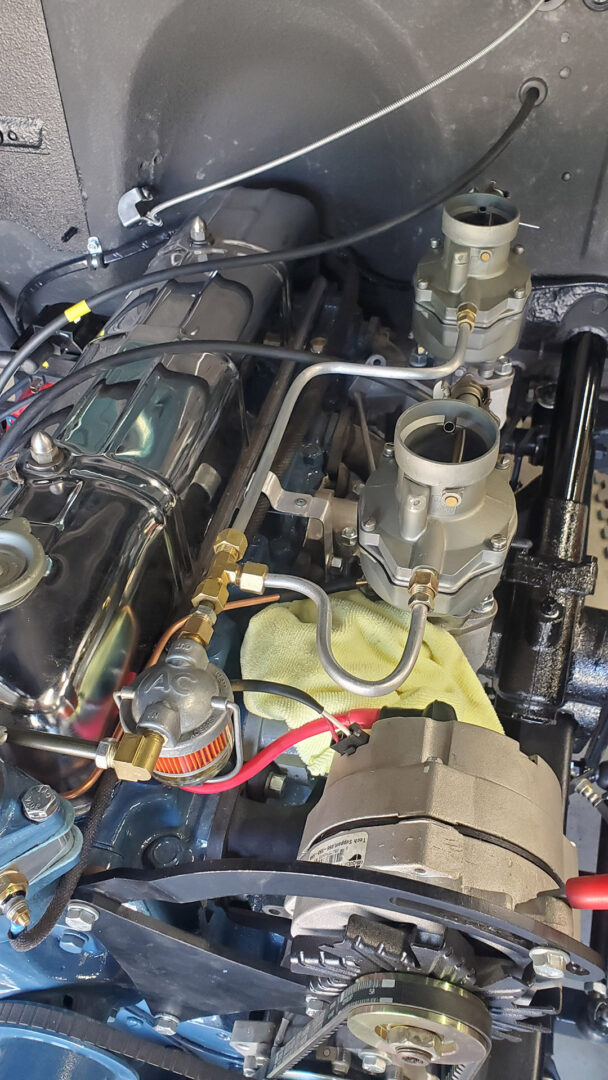

With the rebuilt carbs back in place atop the intake we had new leaks at some of the fittings. I switched out a couple of the compression style fittings for proper inverted flare fittings - which, in turn, required some plumbing gymnastics. So, more mods ensued and we ended up with two fabricated aluminum hard lines.

Unfortunately, at least one of the carbs still leaks fuel like crazy between the bowl and the air horn. My earlier attempts to straighten it, at least in that area FAILED. The new gasket alone is not enough. It's disappointing and frustrating, to say the least.

Will the truck fire and run though? Right on cue, the truck begins to mock me. The ignition is dead. Ugh...

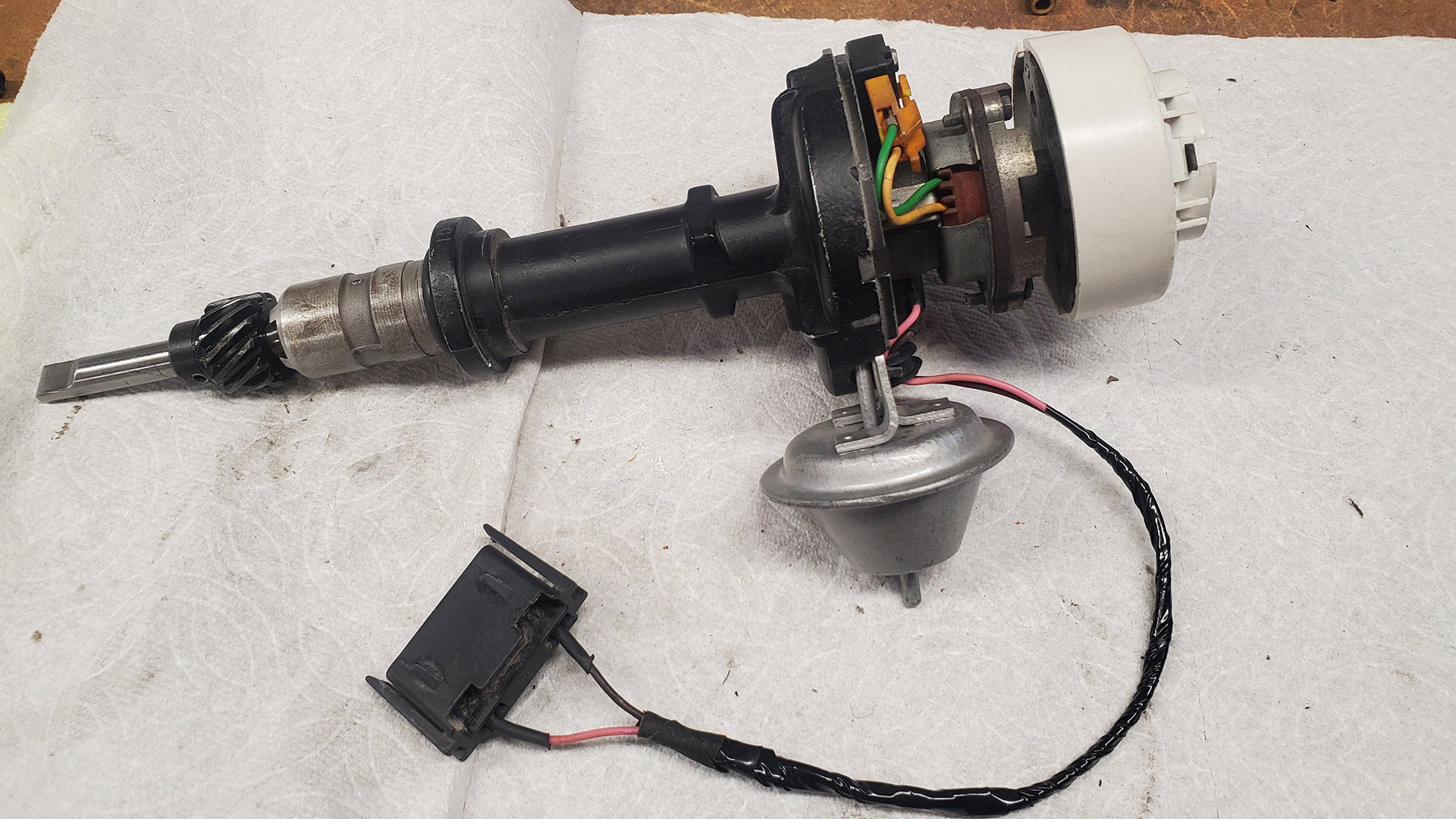

We had spark before. The engine fired. It wanted to run. Now, nothing. We have voltage to the coil. The coil tests good. The pickup inside the distributor still works but the ignition control module seems to have taken a dump.

After a lot of digging to identify it, it appears to have been used through the '80's on a number of vehicles. But for the money and availability..? I don't know. I think we'll retire the system for a newer style HEI ignition.

Our progress is thwarted again.