One Step Forward, Three Steps Back?

After our excursion to the muffler shop (on and off a trailer) it was clear the front brakes were dragging. The 2 lb. residual pressure valves plumbed into our brake lines shouldn't be an issue. So, I pulled the brake master cylinder to look for clues. There's a push rod inside the vacuum brake booster between the booster and master cylinder that you don't see when they're bolted together. They're usually adjustable in length. I failed to check the adjustment a long time ago while putting them together and assumed all was good. If the rod is too long, it will push the piston in the master cylinder and potentially cover a port that shouldn't be covered when your foot is off the brake. Fluid pressure isn't released. It's kinda like having the brakes applied all the time.

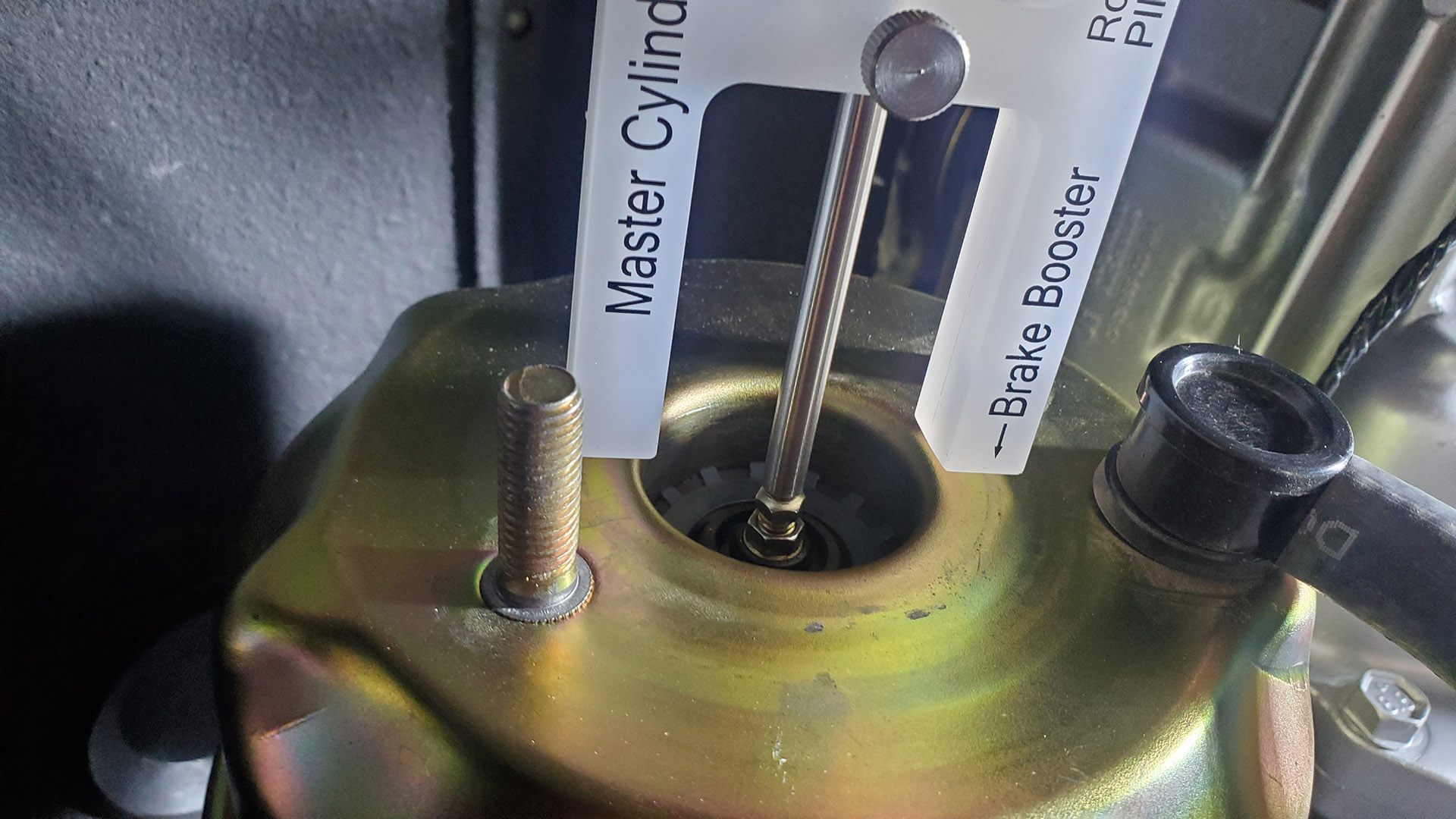

I used a special tool to measure the depth of the hole in the master. Once you find the depth, the rod is locked in place on the tool.

Then you place the other end of the tool on the booster and see if the end of the push rod is too far in, out, or just right. Ideally it would just touch the end of the tool rod.

In this case the booster push rod was pushing the tool away. It was adjusted out about 1/4" too far!

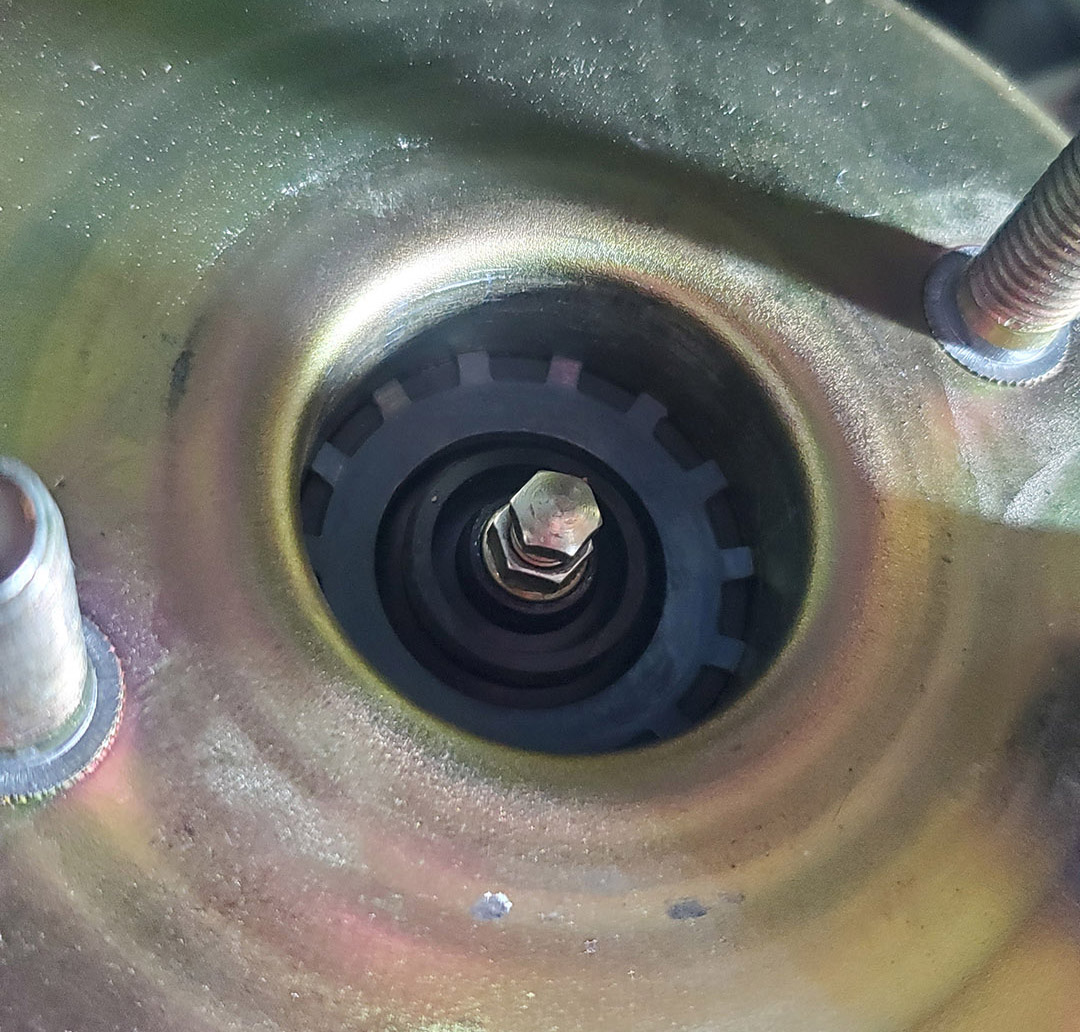

There's a hex on the end of the push rod with a lock nut below it. The whole rod wanted to spin after loosening the lock nut so I couldn't screw the rod end in farther to shorten it. I pulled the booster off and removed a retainer and rubber seal for better access on the bench. Sometimes the rods will just pull out the back but this one wouldn't.

With the end of the rod screwed all the way in it was still a hair too long. I had to file the lock nut to make it a little thinner - basically take all the adjustment out of the rod and then some. This allowed the piston in the master cylinder to return to it's proper resting position.

So, there you go - another lesson to never assume anything. The front brakes don't seem to drag now.

Some test driving around the field here and (ahem!) the neighborhood revealed continued and serious drivability issues. Under a load the engine would cough, sputter, and backfire badly - as if possessed. At other times it seemed perfectly behaved. The truck was definitely not drivable like this.

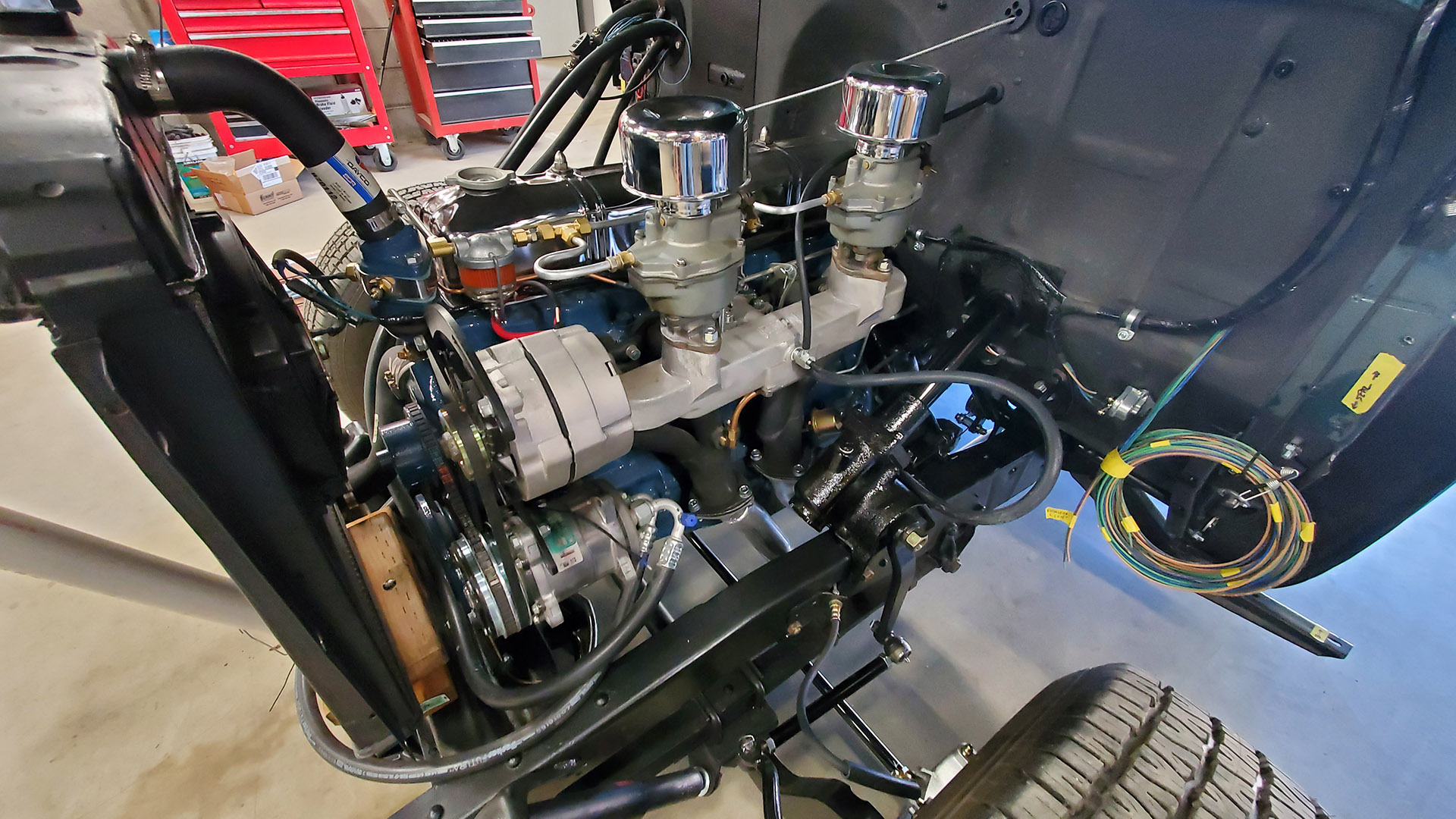

These engines rely on heated intake manifolds to help keep fuel atomized on its way to each cylinder. Originally, the exhaust manifold was bolted directly to the intake with passageways to direct hot exhaust where needed.

In this setup, a copper tube pipes hot exhaust from the headers to a chamber on the bottom of the Fenton intake (which is aluminum and will dissipate heat faster than cast iron). The question became, was it heating enough? The engine had been running remarkably cool with the stock 180* thermostat and electric fan.

As a test I installed a hotter coolant thermostat (195*). It definitely raised the overall engine temperature and that of the intake manifold on a warm day. And while it may have helped drivability slightly, the engine still coughed and sputtered under load. Just keeping the RPM's up was difficult.

That left the already sketchy Rochester carburetors as the likely culprits. Truck owners run dual carb setups all the time and they'll work fine if properly matched and tuned. After discussing options with the owner we came to the decision in this video clip - which I think will be a good one...