Out with the new, in with the old?

With the '50 Chevy 1/2 ton back from the body shop with its frame successfully pulled and prodded back into proper shape we set about undoing some previous work.

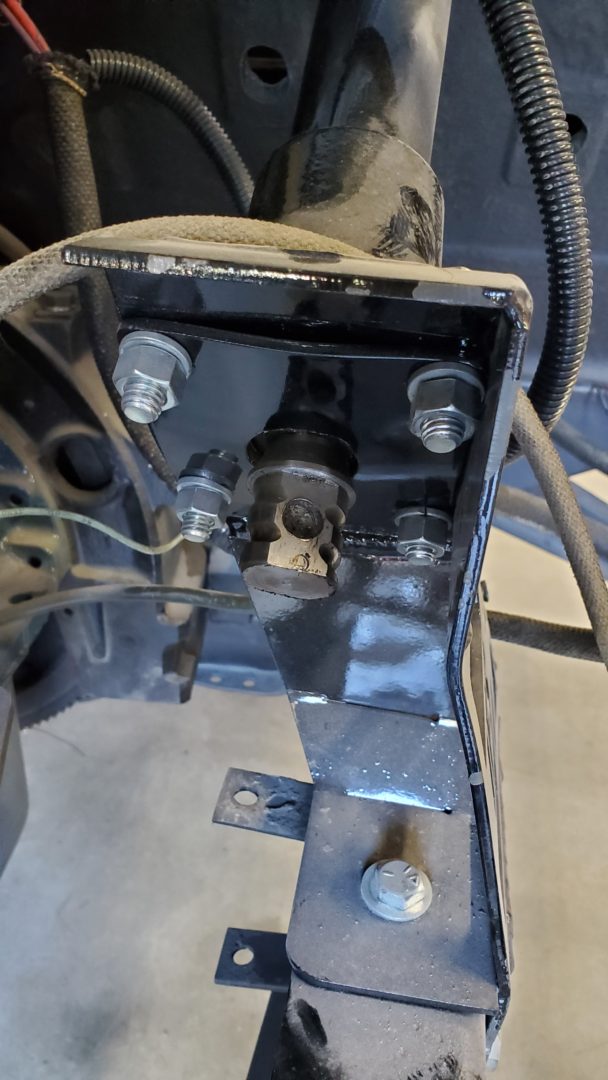

First to come out was the rack and pinion unit bolted to the frame. In our last post we discussed how this configuration just doesn't work well on a straight axle truck.

The previously modified steering column and wheel were also removed. The builder had fabricated a bracket system that bolted in place of the original style gear box. They had cut the worm gear on the end of the steering shaft and machined two flats so that a u-joint coupler could be attached and then linked to the rack and pinion unit.

Clever, but unfortunately none of it could be reused when returning to original steering components.

The pitman arm and steering arms that are bolted to the wheel spindles were pulled from our donor chassis. They used old style ball studs with multi-piece sockets which worked back in the day (till they didn't) but aren't as precise as a modern tie rod end. We're modifying them to accept the latter.

The parts are 'castrated' with a cutoff wheel and the studs removed with a 12 ton press.

The holes for the ball studs are enlarged with a 7 degree tapered ream to accept a more modern tie rod end. Since the truck already has a dropped axle we're mounting the tie rod below the steering arms rather than on top so that it won't interfere with the front springs. So, in this case we ream from the bottom up on the arms. Same for the hole for the drag link on the driver side steering arm. The pitman arm will be reamed so that the rod end nut will be on the inside, next to the frame. Mounting the drag link from the bottom up means the pitman arm shouldn't need to be shortened either.

The left steering arm has a hole for a drag link. It's already a little too large so the old stud was pressed back in, (welded for good measure), drilled out to 1/2", and then reamed to size.

The pitman arm has an even larger oversized hole. It was welded closed and then re-drilled and reamed to size.

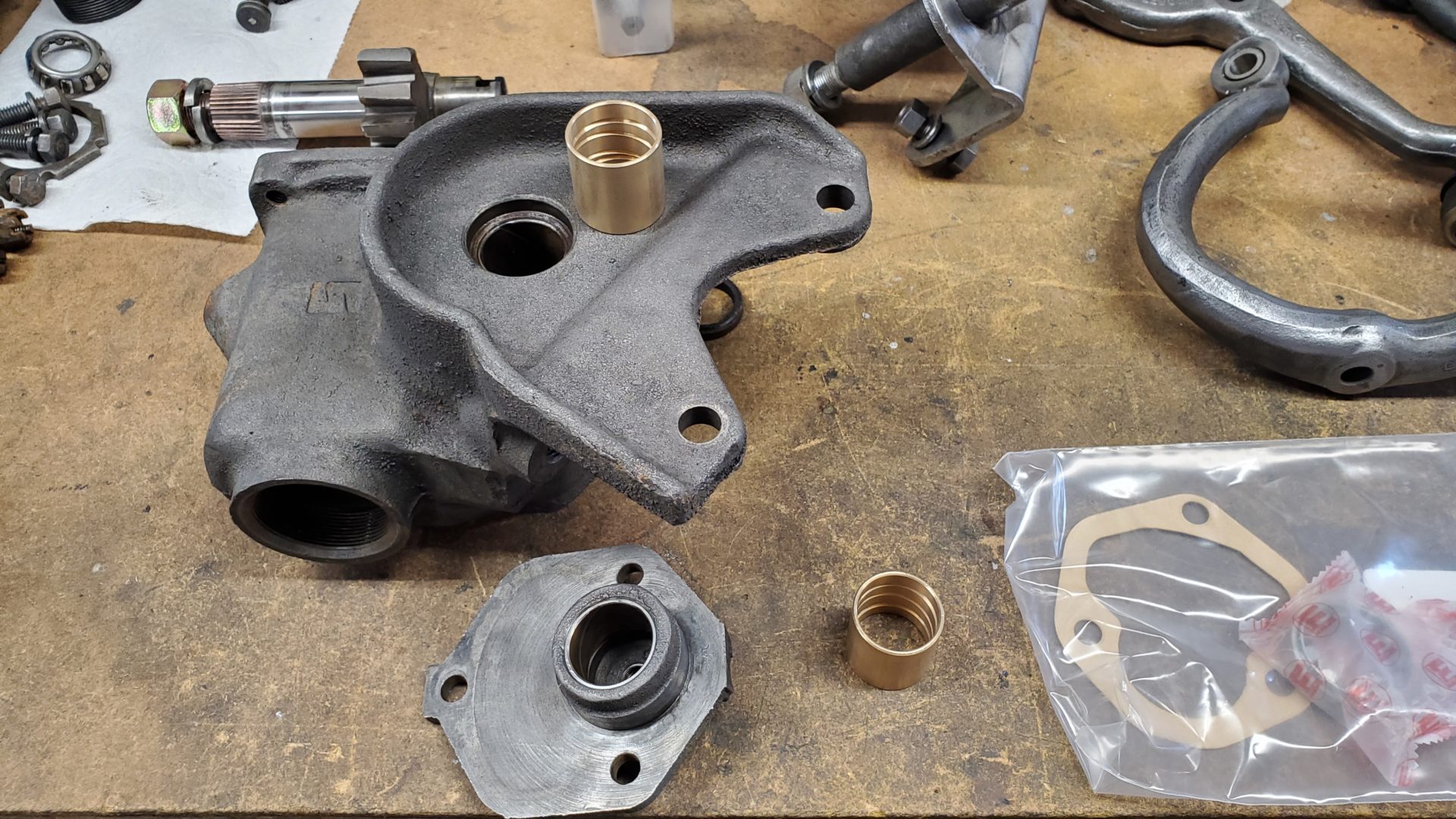

Meanwhile, the donor steering column with gear box is degreased, de-rusted, and disassembled.

Once everything is cleaned up, new sector shaft bushings are pressed into the housing and cover. The worm gear, recirculating balls, and thrust bearings were in good shape so they were left alone.

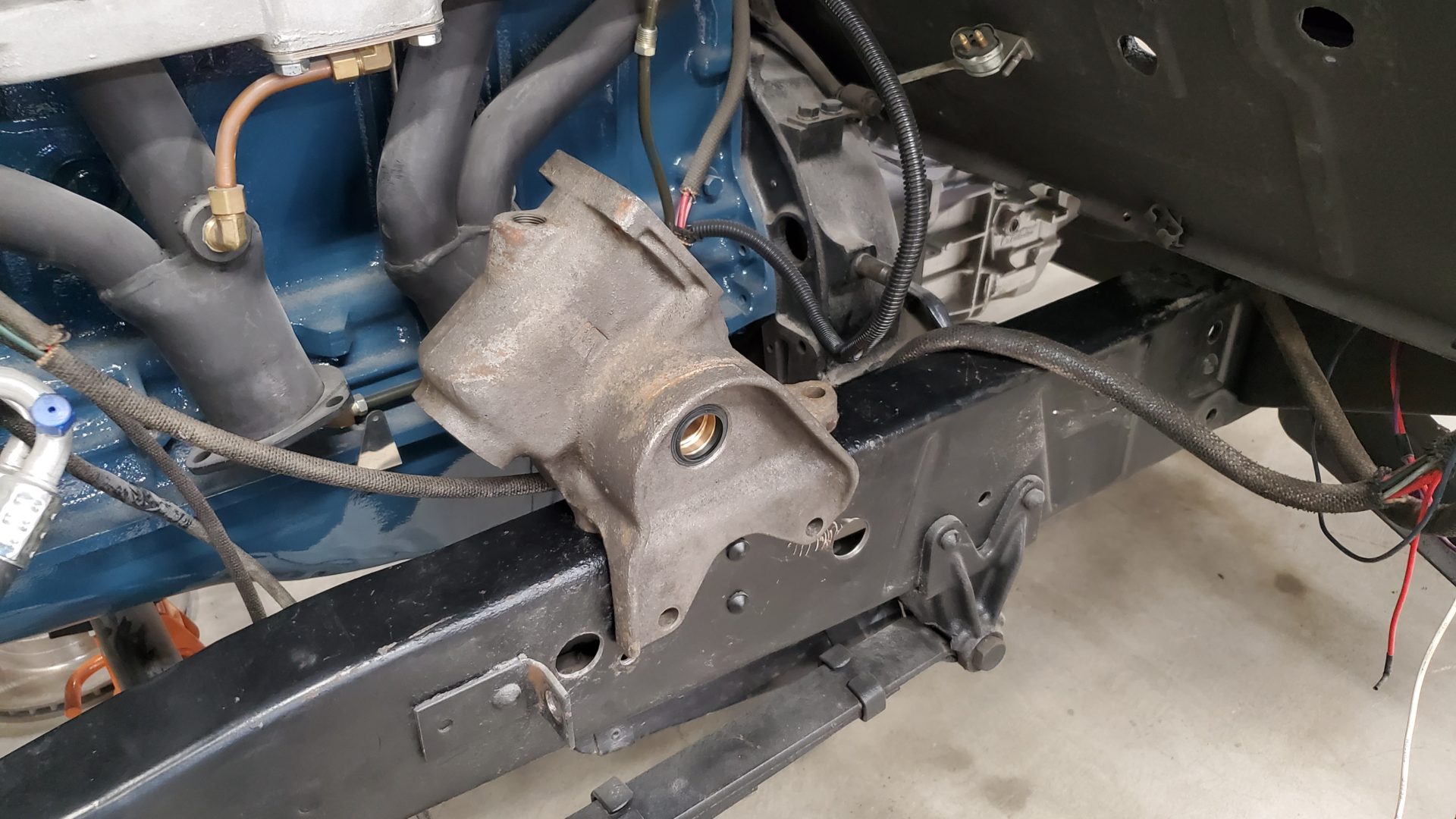

The entire assembly will eventually be mounted back on the frame in it's original position.

The donor column tube was stripped of old paint and rust in preparation for a fresh finish. Then the entire unit was reassembled and adjusted to spec (for 'tightness').

With the steering box overhauled and adjusted and fitted with modern tie rod ends, the truck should steer nicely without any significant slop.

We'll show how all these parts and pieces come back together on the chassis to function as a system in a future post, so stay tuned!