Steering, Rear Suspension, and Transmission Progress – Sort of….

When working on projects like this '50 Chevy pickup it seems like we spend more time waiting on parts that doing the work on it. And it's not like we order one part at a time. Usually it's in batches to save both time and money on shipping. Consequently, we hop from task to task to try and make some progress and move things along.

In this installment we get closer to finishing the steering, we begin mockup on the new rear suspension, and tear into the junk yard T5 transmission for a look.

You'll recall in earlier posts someone had attempted a rack and pinion steering conversion but we determined to return things to a more stock configuration. A donor chassis supplied some missing parts that we modified for some modern upgrades.

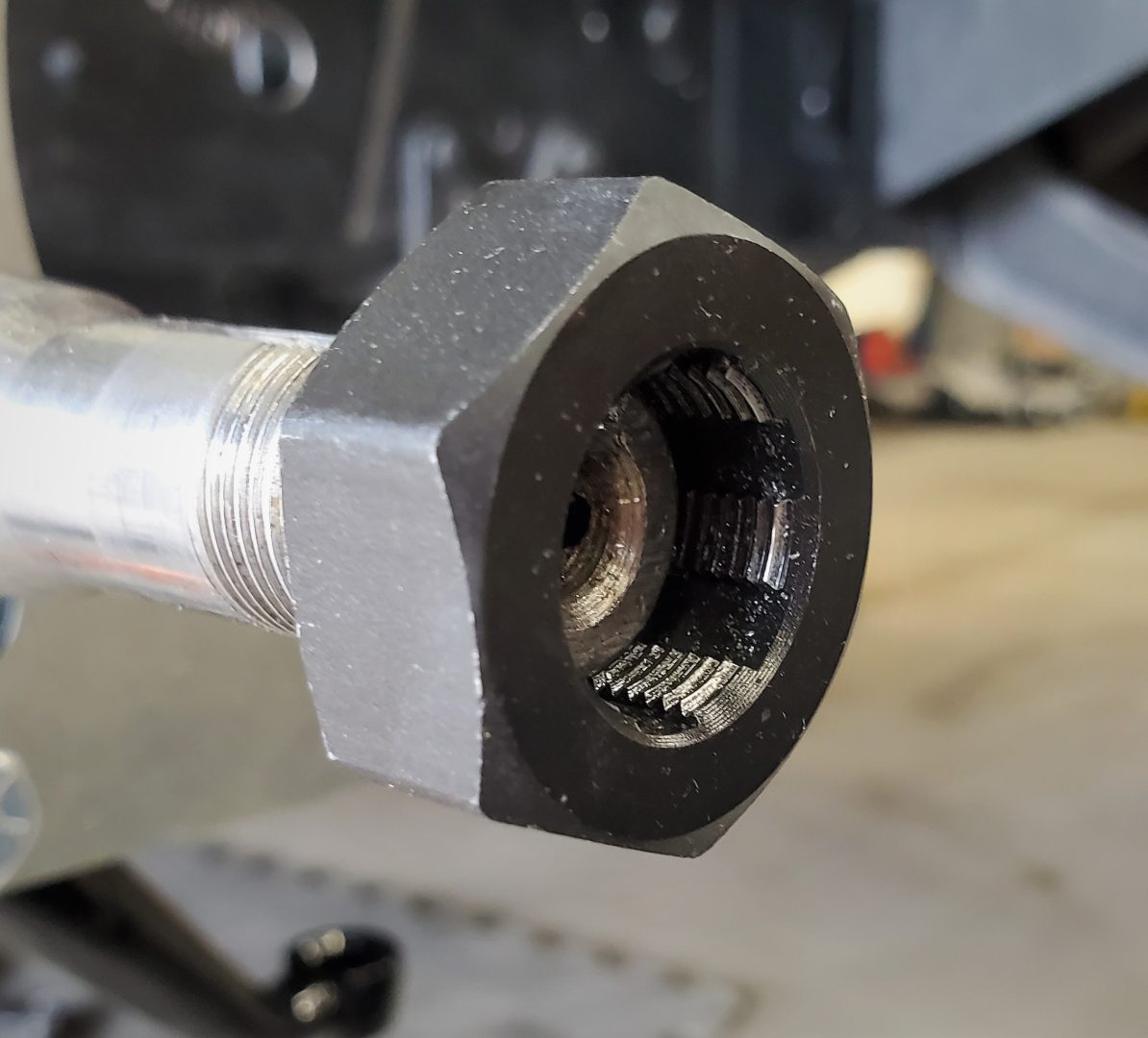

The first task was to repair the fubared threads on one of the wheel spindles. A spindle rethreading die cleaned them up and we grabbed a 'new' nut from our donor.

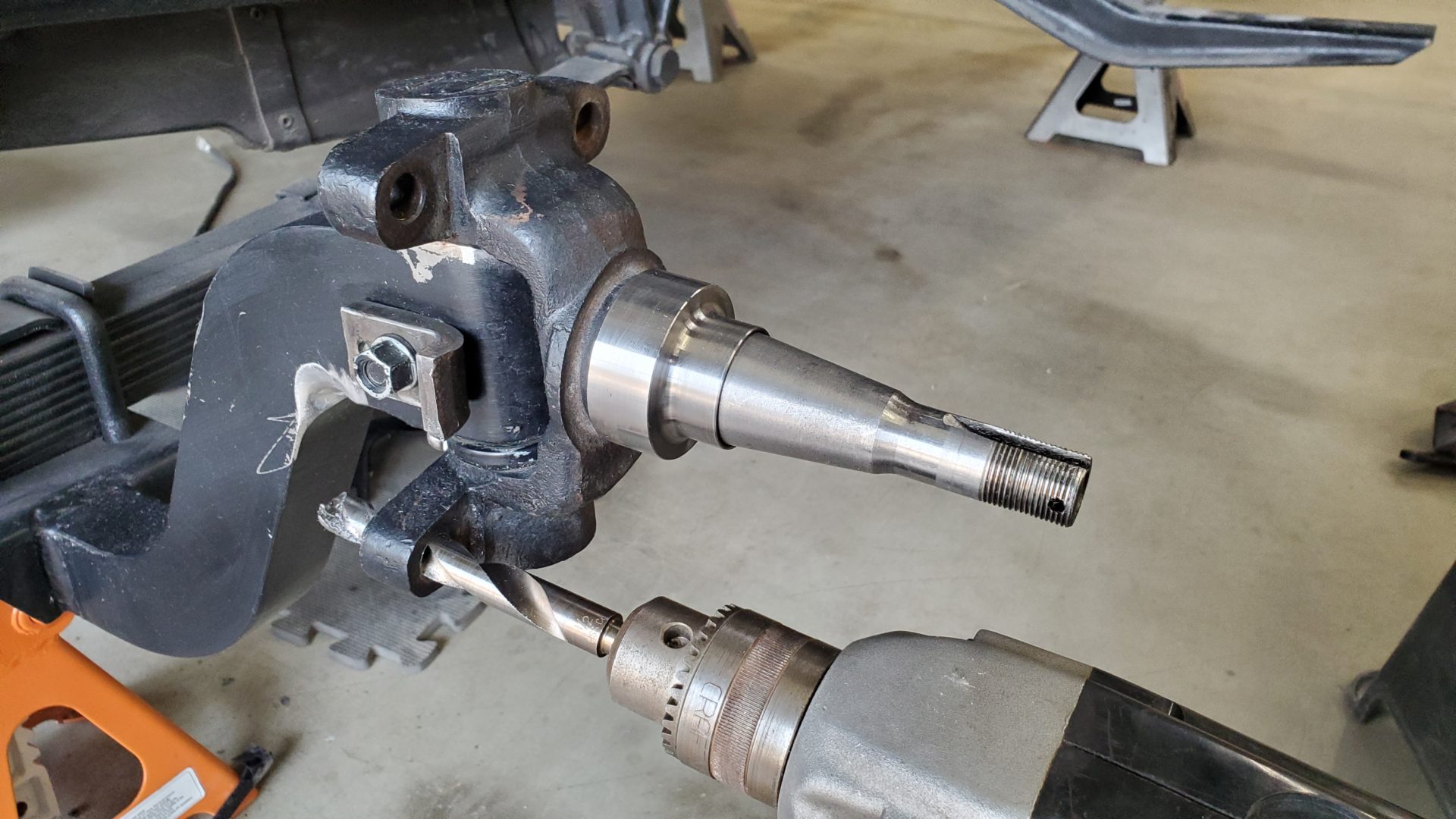

Reinstalling the disc brake conversion from Speedway Motors (manufactured by CPP) required drilling out the lower mounting holes in the spindles and steering arms for larger bolts - 7/16" to 1/2".

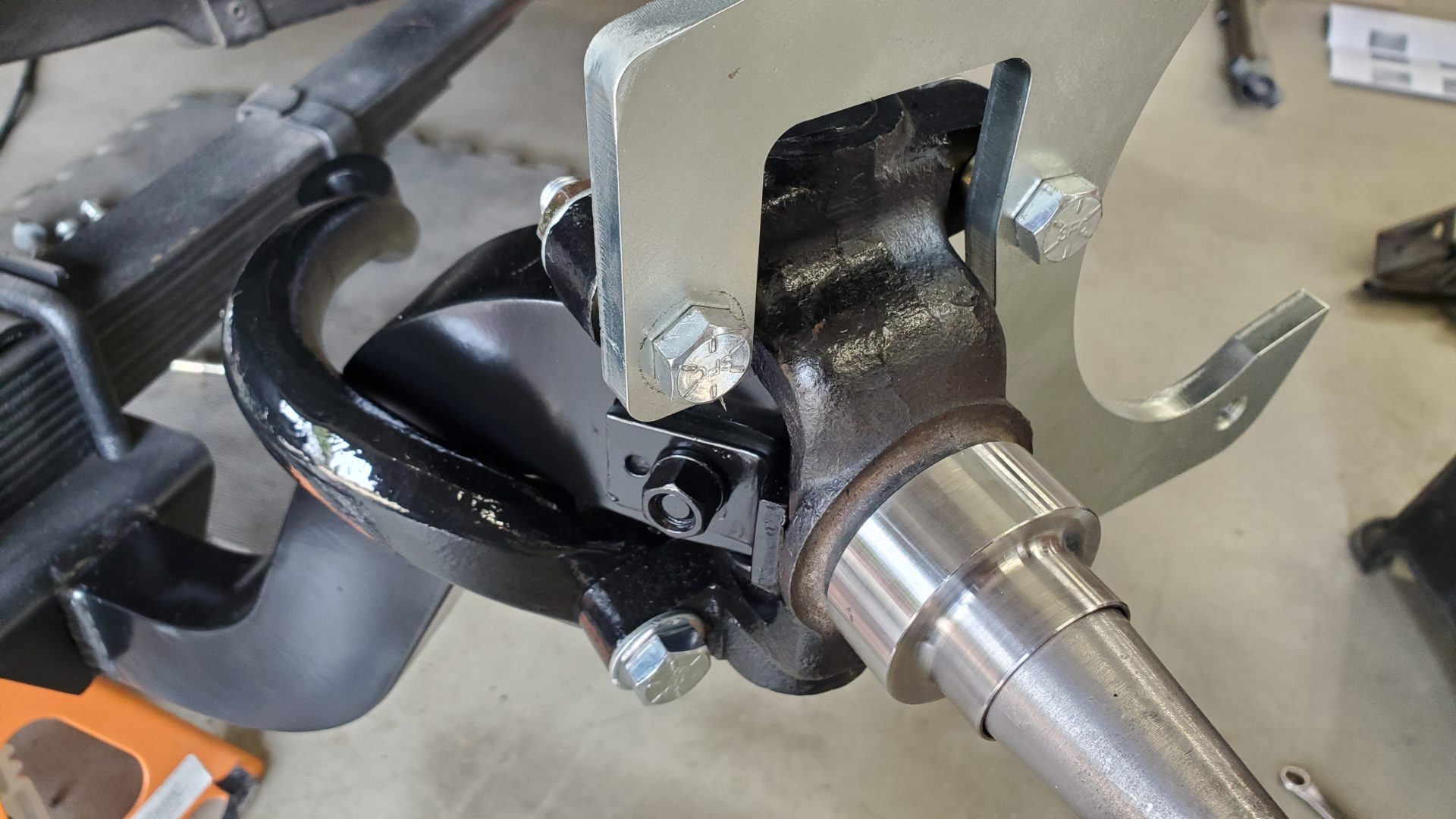

The aftermarket 3" drop axle, with billet steel ends, is bulkier than the stock I-Beam axle. Some clearancing with a die grinder was required so that the stock steering arm would not interfere with it at a full right turn.

With the caliper bracket and steering arms bolted to the spindles the brakes can be reassembled. The kit uses calipers for a '70-'77 Camaro (or equivalent). Unfortunately we found the calipers also interfere with the axle before a full turn can be made, making for a reduced turning radius. So, we'll probably do a little clearancing on the axle to improve the turning radius and modify the steering stop so it can do its job. The brake caliper should not serve as the steering stop.

We also begin mockup on the new leaf spring rear suspension, which will lower the altitude at the back of the truck to match the front.

New hangers attach where the old ones were riveted and the new springs hung.

A new tubular cross member serves as a mount for the shock absorbers inside the frame.

The junk yard donor axle housing from a 4x4 S10 Blazer is temporarily set in place atop the springs. This axle will fit and work much better than the late Camaro unit that was in it.

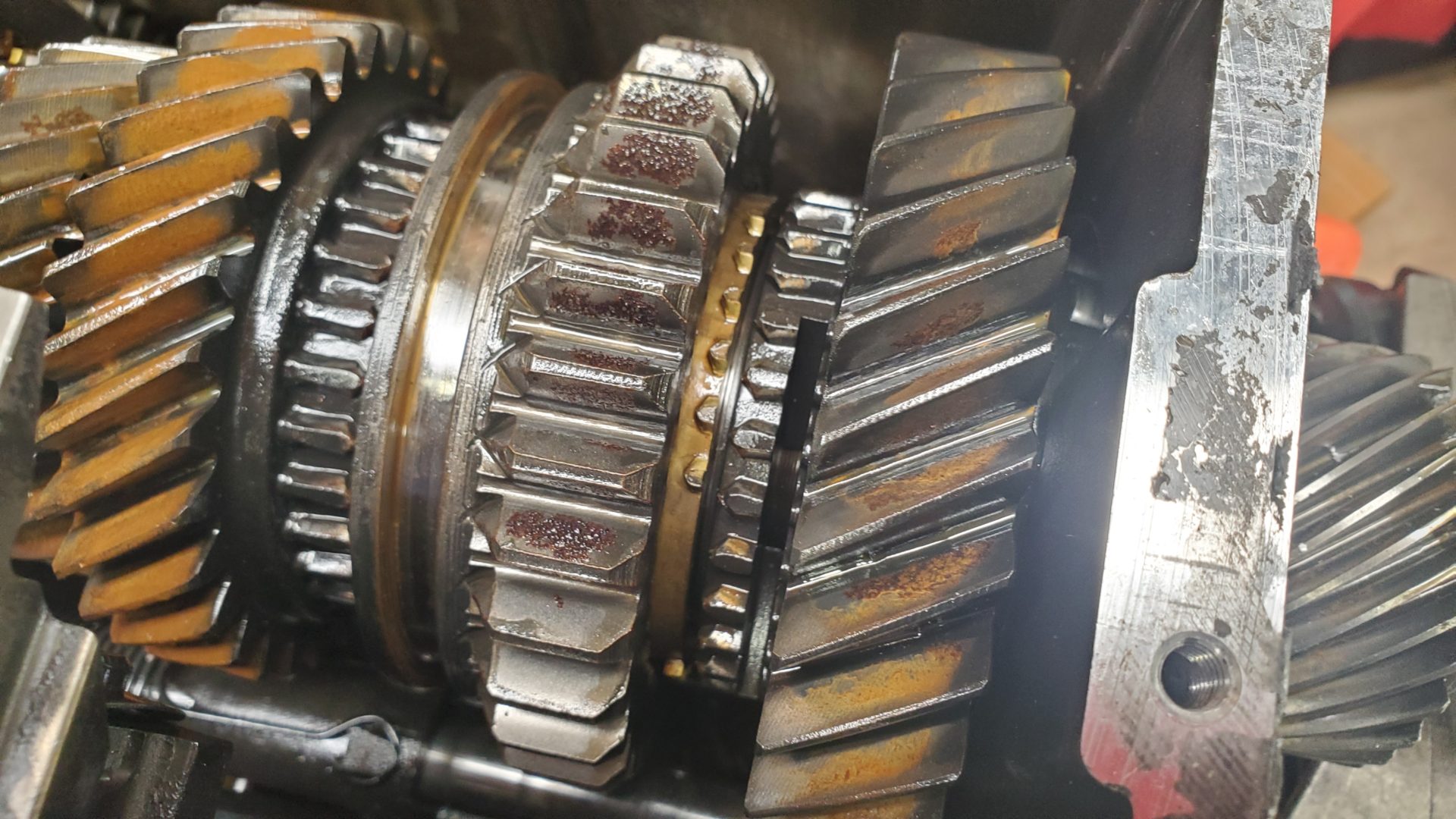

And finally, we took a look inside the T-5 transmission someone had swapped into the truck. It's also from an S10 and sported a suspicious coat of silver paint right over caked-on dirt and grease.

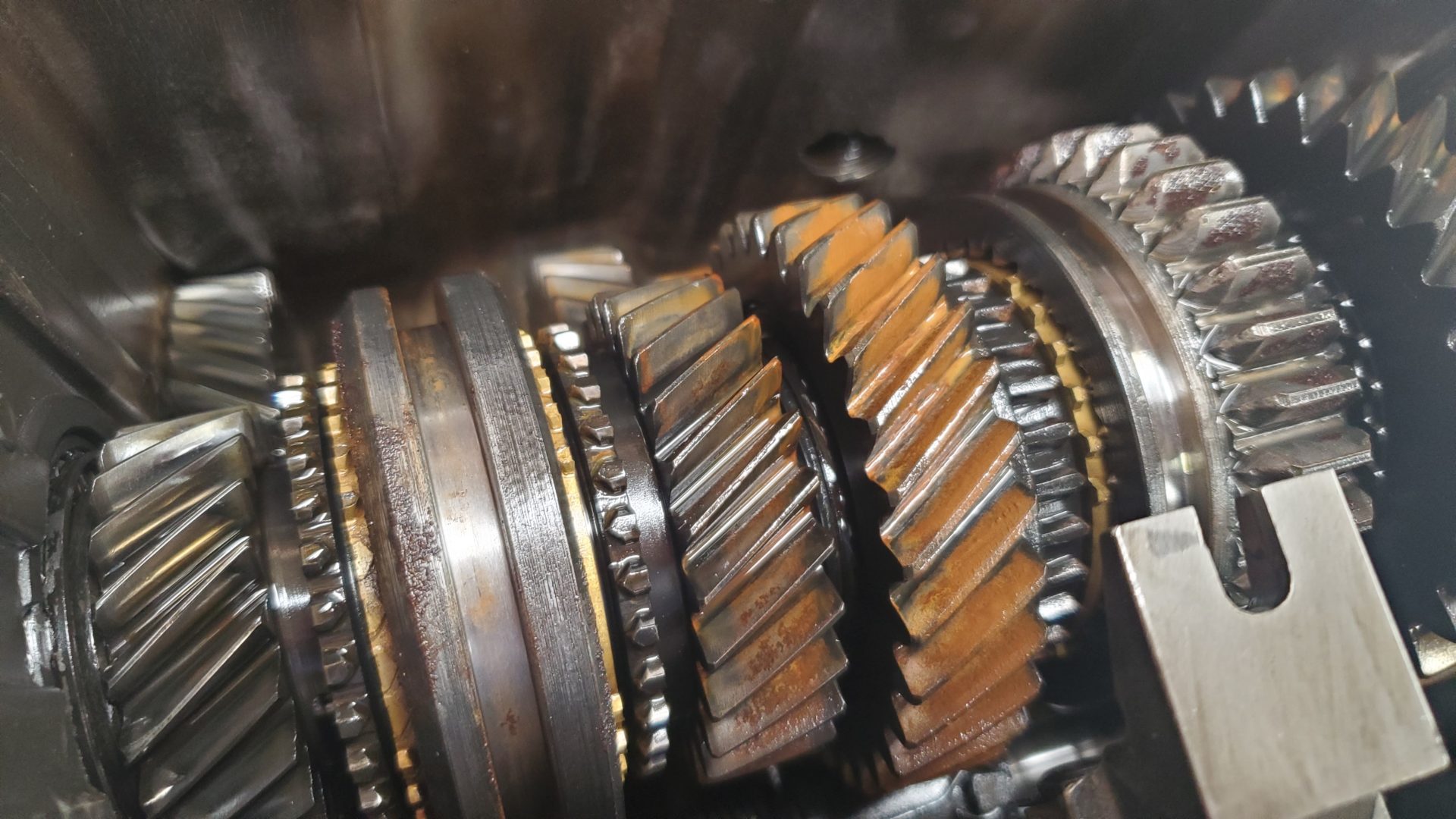

Most of the oil was already drained out. After removing the tail shaft housing and popping the top we found.... (wait for it...) rust! Obviously some moisture got in at some point, probably mixed with the oil, and did its thing.

Some of the rust is light surface staining on the gears which should clean off okay. But other rust (which looks like dirt in the photos) is thicker and scaly. The guts are going to have to come out and be cleaned up. Hopefully, we'll get lucky and not have to replace parts. And while it's apart, we'll swap in a 10 spline input shaft to eliminate the home made (and unusable) spacer plate.

It would be nice to be able to avoid a rebuild. We'll see.