“The Cab That Breathes” (or Poor Man’s A/C)

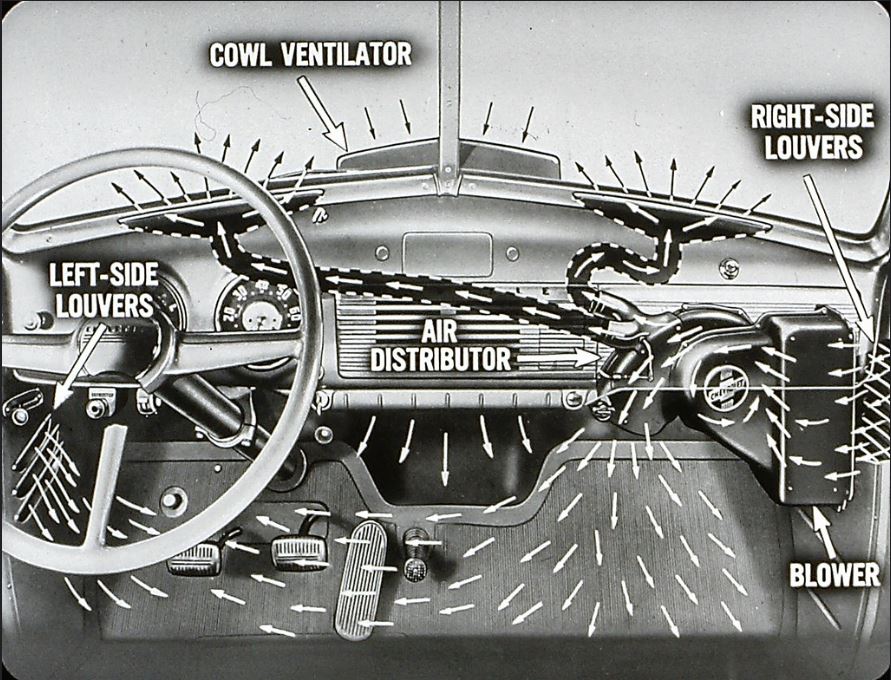

Marketed by GM as "the cab that breathes" this 1950 Chevy 1/2 ton has not one but two cowl vents. The 'Cowl Ventilator' is a hand operated scoop of sorts that pops up in front of the windshield to allow gobs of fresh air to flood inside. If that's not enough, a second door on the driver side of the cowl can also be openend via another lever.

The former door was in a box, painted and ready to install. The latter was missing altogether.

1950 was the last year of the cowl side vent. No one reproduces this part and the earlier versions use a different handle on the inside that really isn't interchangeable. So, we turned to Ebay early in the project and got lucky to find and score the correct fitting part. Though thoroughly rusty on the back side, it was in good shape. A soak in a special chemical dissolved the rust (media blasting is an alternative). We stripped the remaining paint and were left with a part ready to prep for a matching paint finish.

The main vent on top of the cowl requires a seal to keep water from entering the cab. The opening does have a 'gutter' system built in to drain water that collects around the edge of the opening through a tube in the engine compartment.

There are three choices for a seal: a plain foam gasket, a simple, flat rubber version, or a properly molded seal that will allow the door to close and seal like the original. We went with the molded one from Steele Rubber Products (#60-0124-54). The company, one of the best on the market, makes all kinds of rubber products for car/truck restoration.

Once, installed and adjusted, the door can be moved to three positions to suit your fancy. Pretty neat. Here it is in action....

To finish things off, a new drain tube is installed and sealed around the firewall. Yup, it's supposed to angle to one side at the end.