What’s the Diff?

Diff: Short for Differential... Actually, let's talk about the entire rear axle.

No, wait. On second thought it's time to address the complete drive train from the engine back - including the rear suspension.

Here's what's going on. When the truck came in we noticed some funkiness with the rear axle - location, tire to fender clearance, stuff like that. It didn't help that the frame was bent. Originally it would have had an axle similar to our donor chassis with an enclosed drive shaft (called a torque tube) that articulated off the rear of the transmission and at the leaf springs. Just old, old tech.

Along with a more modern T-5 transmission, someone replaced the rear axle with what we identified as fourth generation Camaro (1993-2002), including disc brakes. It was mounted to the leaf springs with the same, original style pivot/bushings as the vintage axle. This would explain the use of the the torque arm from a Camaro that runs from the differential up to the transmission. The purpose of the torque arm on the Camaro is to help control axle windup. Here, it would be required to keep the axle from wildly rotating or pivoting up and down. Okay, a hybrid mix of old and new.

Aside from booger welds and crooked brackets, the main problem with the Camaro axle is it's just too wide for the truck. 5" too wide. We don't want to risk tires rubbing on the fenders. An early Camaro axle (late 60's) would actually have been a good fit and width.

The second issue is the truck has an aftermarket 3" drop axle on the front. Nothing wrong with that. It'll sit lower and look better. But the rear suspension was at stock height - too high, compared to the front, for a stink bug stance going down the road. The solution is a new and simplified leaf spring rear suspension that'll drop it around 4" and complement a narrower axle. Not as 'exotic' as say, a 4 link with coilovers, but less expensive and better in keeping with the old school design. And, it won't have the goofy pivots at the spring perches.

We sourced a 'modern' axle that is the correct width (about 60" hub to hub) from EZ Auto Wrecking nearby. In this case, it's from a 2004 S10 Blazer 4X4 with 5 lug wheels and disc brakes. It has a 3.42 gear ratio that'll be a good match to the S10 T-5 transmission (4.03 first gear, .86 fifth gear) someone already (sort-of) installed. We'll freshen up the hardware, brake pads, seals, etc. And, we'll have to swap the metric 12mm wheel studs out to match the 7/16" studs in the front. Otherwise the bolt pattern is the same.

The Camaro axle and shocks are unbolted and removed, followed by the original leaf springs, shackles, and hangers.

Rivets that attach the old cast iron spring hangers to the frame are ground and driven out. All of it will be replaced with a kit made by TCI from Speedway Motors.

We found rust/cancer under one of the old spring hangers that had rotted all the way through the frame. The rot is cut out and a patch welded in to restore some strength.

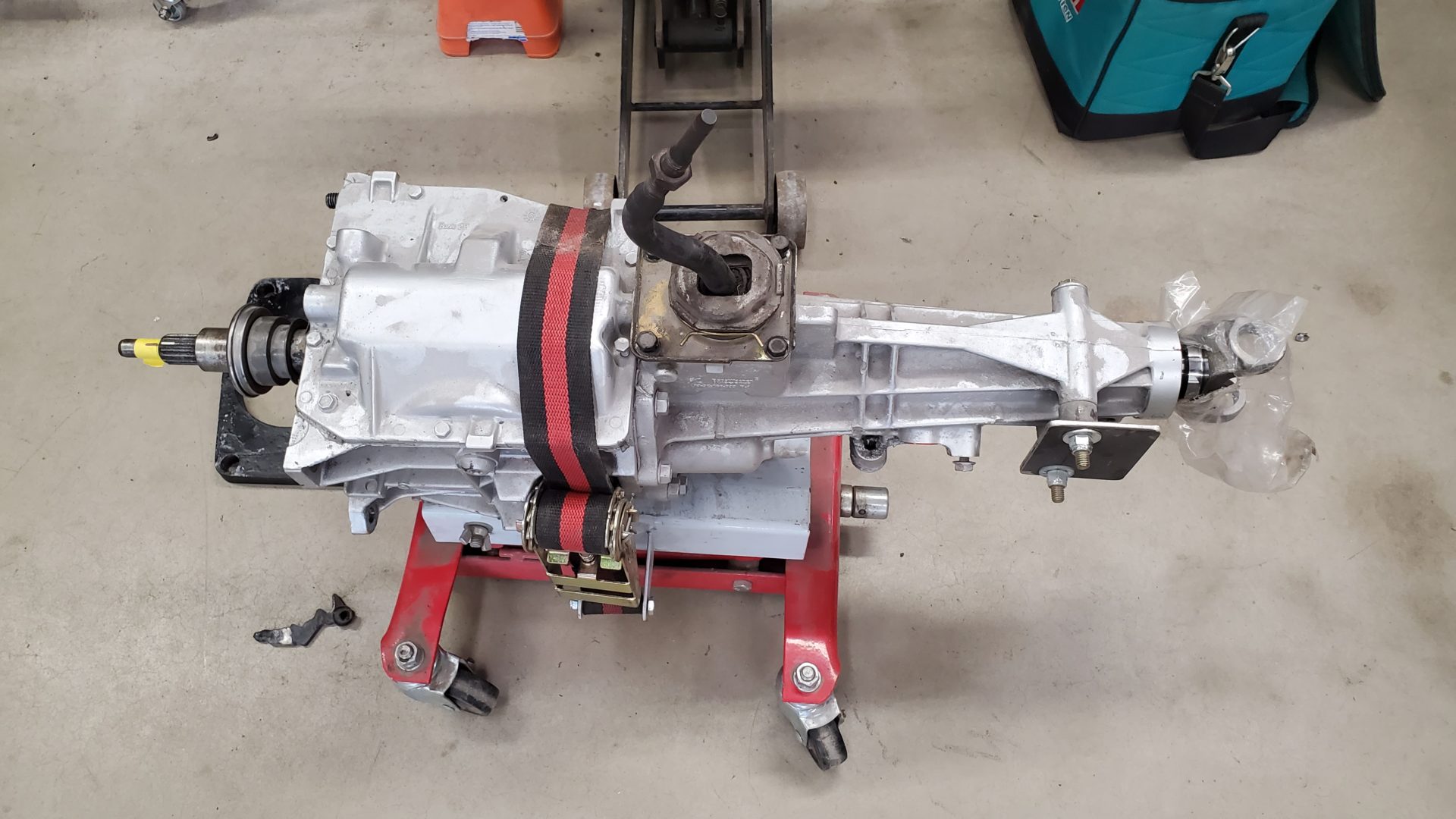

After unbolting the T-5 transmission we found more issues. Since the input shaft is a little too long an easy way to adapt the transmission to the early engine and bell housing is with a spacer plate. Normally the plate would be machined for a reasonably precise fit. In this case a home-made spacer (3/4" steel) was used but it doesn't 'register' (or accurately align) the transmission to the bell housing properly. The center hole is way too big, amongst other things.

The 5 speed transmission deserves a look inside to check the condition. The tag and factory sticker are missing which would give us a lot of helpful information. Based on appearance we can tell that it came from an S10 truck with casting dates of 1991 - so it's from around that period.

The plan is to change the input shaft to a slightly modified 10 spline used in a T-5 for Jeeps. This will do away with the spacer plate and allow the trans to properly align with the bell housing. The clutch package currently bolted to the flywheel is still in question.

Stay tuned to see it all come together!