“Whoa, Nellie!”

Initial test drives of the '66 Mustang proved that an upgrade from manual drum brakes to disc was good (and better yet with a quality pad), but still required more 'leg effort' than we think the owner will be comfortable with. So, we're in the process of retrofitting power brakes to the system.

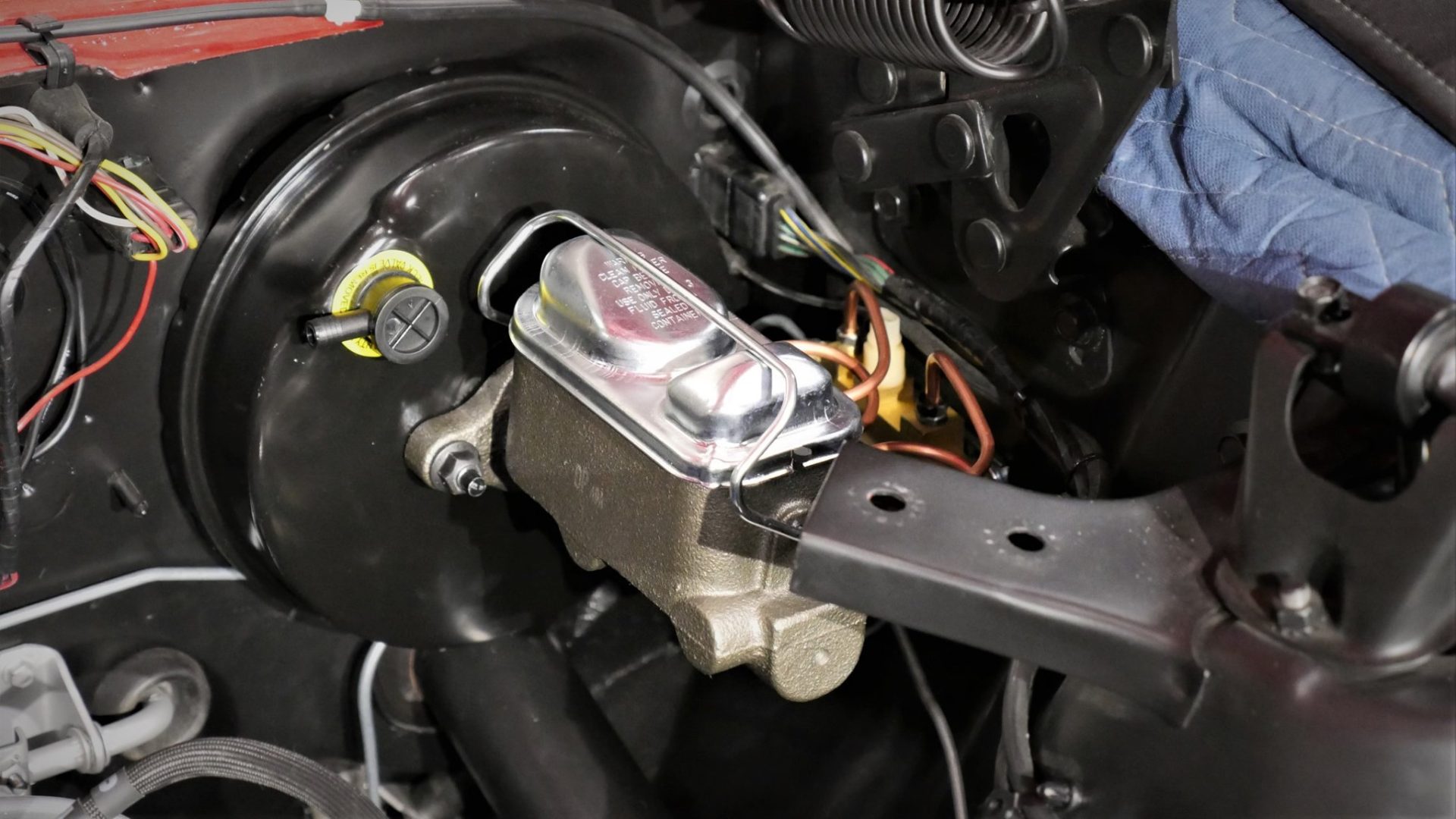

This involves adding a vacuum booster to the firewall, modifying the pedal bracket under the dash as well as the brake pedal itself to change the ratio when pressed.

We'll see what the improvement is after the system is refilled with fluid and bled of air.

The brake pedal hanger is removed from under the dash and cut so a reinforcing place with different mounting holes can be welded added.

The assembly is upside down in this picture with the brake pedal pointing up. A hole is drilled in the pedal arm and a new pin welded in which changes the ratio when pressure is applied. It's just tack welded in place here so we can check fit.

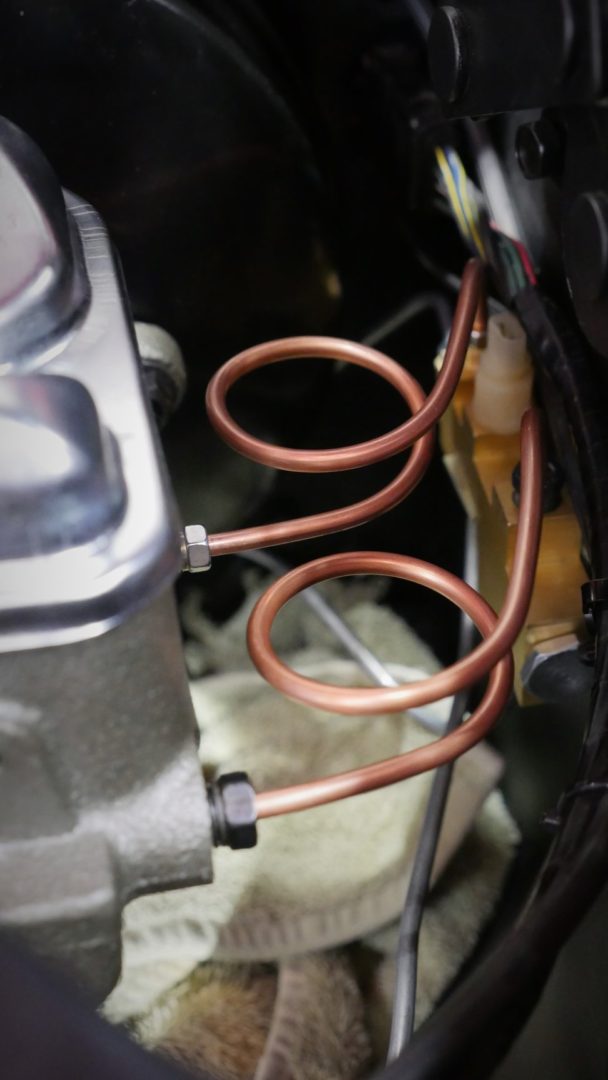

New brake lines are required to run from the master cylinder to proportioning valve. We fabricate new lines using Nicopp (nickel/copper) which is easy to work with won't rust like steel.

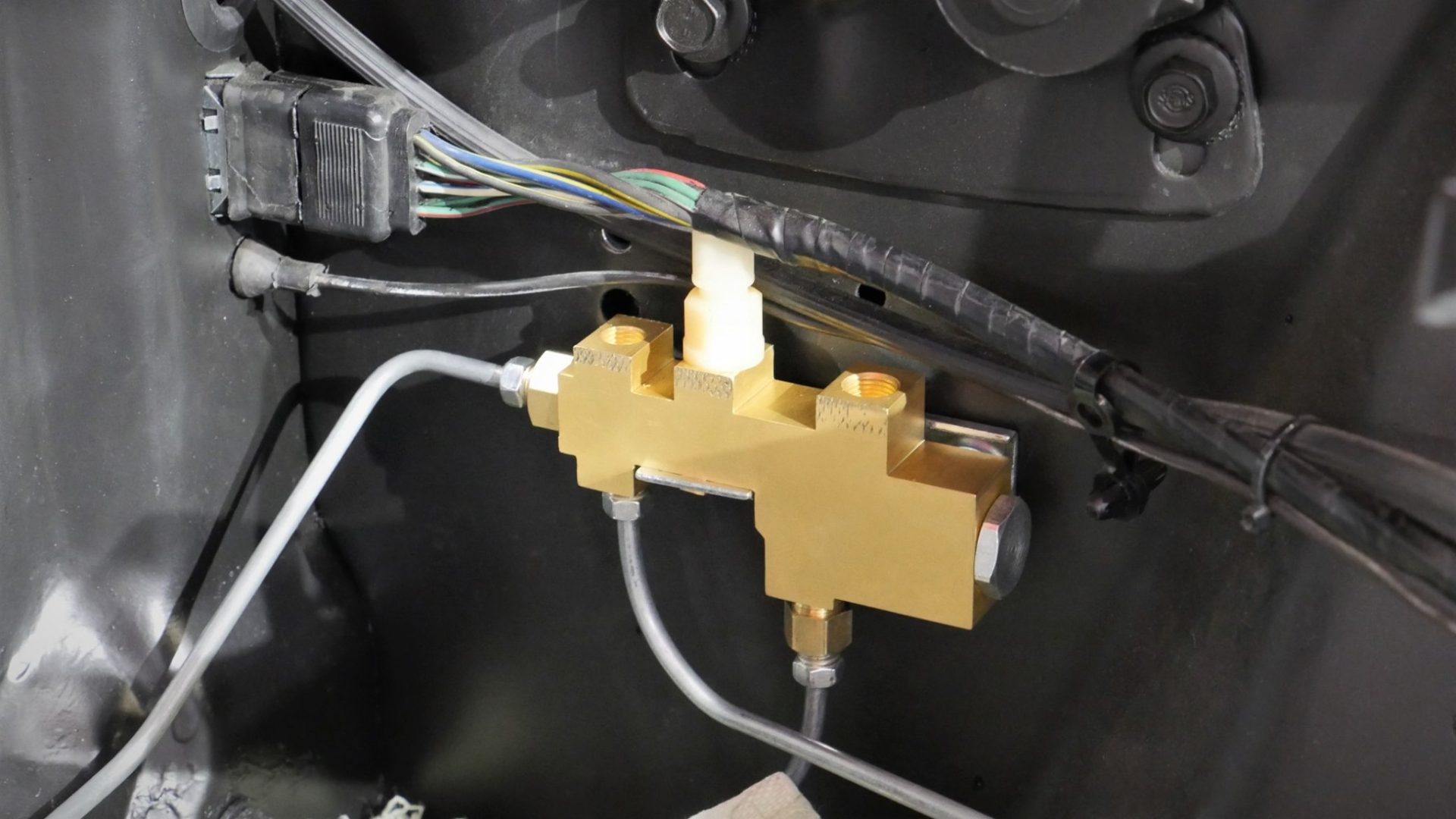

A tube nut compresses the flare and seals the joint in the companion half of the inverted flare - found on the master cylinder and proportioning valve.

Everything is mocked up and fitted. Just need to tighten lines, bleed the system, and connect the booster to a vacuum source on the engine.